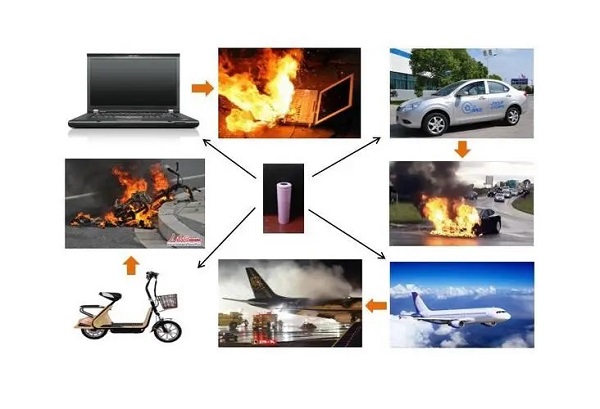

The advantage of new energy vehicles is that they are more low-carbon and environmentally friendly than gasoline-fueled vehicles. It uses unconventional vehicle fuels as its power source, such as lithium batteries, hydrogen fuel, etc. Lithium-ion batteries are also used in a wide range of applications, including new energy vehicles, mobile phones, laptops, tablets, mobile power supplies, electric bicycles, power tools, etc.

However,

the safety issues of lithium-ion batteries cannot be underestimated.

Many accidents have shown that when people charge improperly or the

ambient temperature is too high, it is very easy to cause spontaneous

combustion and explosion of lithium-ion batteries. This has also become

the biggest pain point in the development process of lithium-ion

batteries.

However,

the safety issues of lithium-ion batteries cannot be underestimated.

Many accidents have shown that when people charge improperly or the

ambient temperature is too high, it is very easy to cause spontaneous

combustion and explosion of lithium-ion batteries. This has also become

the biggest pain point in the development process of lithium-ion

batteries.

Although the properties of lithium batteries

themselves determine their fate of being "flammable and explosive", it

is not completely impossible to reduce risks and safety. With the

continuous advancement of battery technology, whether it is a mobile

phone company or a new energy vehicle company, through reasonable

battery management systems and thermal management systems, batteries can

ensure safety and will not explode or spontaneously ignite.

1. Improve the safety of electrolyte

There

is a high reactivity between the electrolyte and the positive and

negative electrodes, especially at high temperatures. In order to

improve the safety of the battery, improving the safety of the

electrolyte is one of the more effective methods. The potential safety

hazards of the electrolyte can be effectively solved by adding

functional additives, using new lithium salts, and using new solvents.

According

to the different functions of additives, they can be mainly divided

into the following categories: safety protection additives, film-forming

additives, cathode protection additives, stabilizing lithium salt

additives, lithium precipitation-promoting additives, current collector

anti-corrosion additives, wettability-enhancing additives, etc.

2. Improve the safety of electrode materials

Lithium iron phosphate

and ternary composite materials are considered to be low-cost,

"excellent safety" cathode materials and may be widely used in the

electric vehicle industry. For positive electrode materials, a common

method to improve their safety is coating modification. For example,

surface coating of the positive electrode material with metal oxide can

prevent direct contact between the positive electrode material and the

electrolyte, inhibit the phase change of the positive electrode

material, and improve the safety of the positive electrode material. Its

structural stability reduces the disorder of cations in the crystal

lattice to reduce the heat generated by side reactions.

As

for the anode material, since its surface is often the part in the

lithium-ion battery that is most prone to thermochemical decomposition

and heat release, improving the thermal stability of the SEI film is a

key method to improve the safety of the anode material. The thermal

stability of negative electrode materials can be improved through weak

oxidation, metal and metal oxide deposition, polymer or carbon coating.

3. Improve battery safety protection design

In

addition to improving the safety of battery materials, commercial

lithium-ion batteries adopt many safety protection measures, such as

setting up battery safety valves, hot-melt fuses, connecting components

with positive temperature coefficients in series, using thermally sealed

diaphragms, loading special protection circuits, and special battery

management systems, etc., are also means to enhance security.

BENZO Energy Technology Co.,Ltd

UFine Technology Co., Ltd

![]() TEL: +86-755-84822012

TEL: +86-755-84822012

![]() TEL: +86-13538185686

TEL: +86-13538185686

![]() Email: contact@benzoenergy.com

Email: contact@benzoenergy.com

![]() Email: sales02@benzoenergy.com

Email: sales02@benzoenergy.com

![]() Email: sales03@benzoenergy.com

Email: sales03@benzoenergy.com

![]() Email: sales01@benzoenergy.com

Email: sales01@benzoenergy.com

![]() Skype: benzobattery1231@gmail.com

Skype: benzobattery1231@gmail.com

![]() Office Address:Building C1, Bantian International Center, BanTian Street, Longgang area, Shenzhen City, China

Office Address:Building C1, Bantian International Center, BanTian Street, Longgang area, Shenzhen City, China

![]() Factory Address 1: Luoma Second Bridge, Tiansheng Lake Villager Group, Luoma Village, QingXi Town, DongGuan, China

Factory Address 1: Luoma Second Bridge, Tiansheng Lake Villager Group, Luoma Village, QingXi Town, DongGuan, China

![]() Factory Address 2: Building

41, Zhongnan HighTech Rongzhi Chuangmei Industrial Valley, Siqian Town,

Xinhui District, Jiangmen City, Guangdong, China

Factory Address 2: Building

41, Zhongnan HighTech Rongzhi Chuangmei Industrial Valley, Siqian Town,

Xinhui District, Jiangmen City, Guangdong, China

Site: www.bz-battery.com / www.benzoenergy.com

Comments

Post a Comment